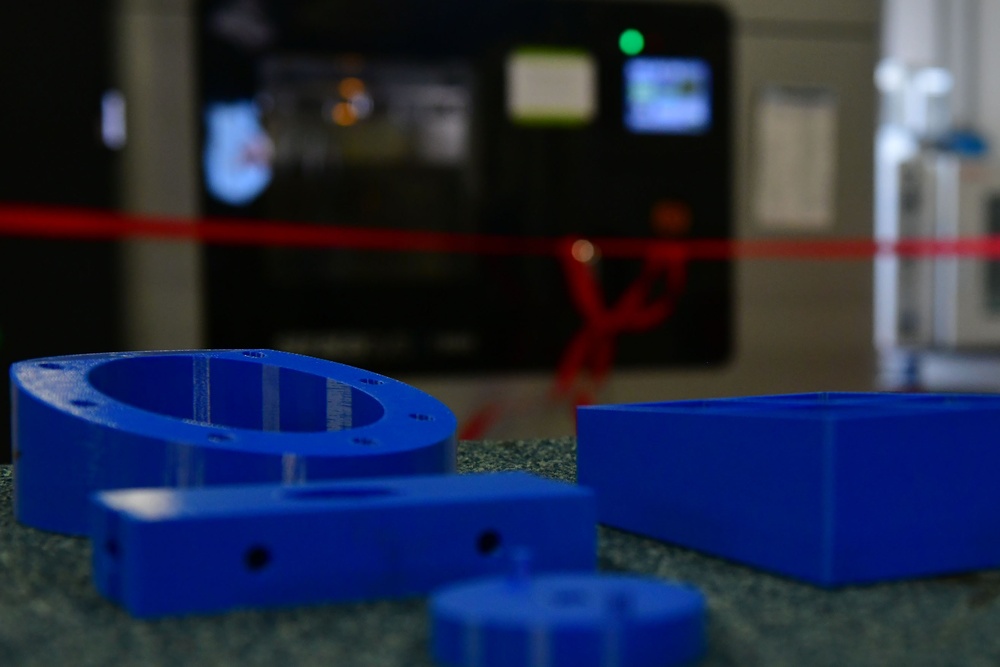

3D printed parts are placed in front of the new 31st Maintenance Squadron metals shop’s Stratasys F900 3D printer prior to a ribbon cutting ceremony at Aviano Air Base, Italy, July 12, 2024. The 31st MXS fabrication flight produces about 63 local manufactured tools per year, and over 350 minor aircraft components per year and with the potential man hour and material savings by this new technology, those numbers could increase significantly by 2025. (U.S. Air Force photo by Staff Sgt. Heather Ley)

| Date Taken: | 07.12.2024 |

| Date Posted: | 07.15.2024 05:19 |

| Photo ID: | 8529134 |

| VIRIN: | 240712-F-FG548-1004 |

| Resolution: | 2632x1755 |

| Size: | 245.18 KB |

| Location: | IT |

| Web Views: | 34 |

| Downloads: | 4 |

This work, 31st MXS metals shop new 3D printing capability will save man hours, money [Image 7 of 7], by SSgt Heather Ley, identified by DVIDS, must comply with the restrictions shown on https://www.dvidshub.net/about/copyright.